TheRobotStudio on YouTube is doing an open source robot called "Hope-Light" and inviting his viewers to follow along with his progress . I have decided to follow along, although I will be modifying his designs as I go to customize it more to my liking. He expressed he wants this to be a open source community to advance humanoid robotics development in the DIY space and usher in the wider adoption of humanoid robots in more homes across the world. He's excited for what this can mean for global productivity and quality of life improvements it can bring if executed well. I like this vision.

My decision to follow along with his project is to pick up a extra head of steam in my own humanoid robot building projects by utilizing his experience and formal education in robotics engineering as a legit decorated world class humanoid roboticist. A world leader in the field. By following his open source project loosely, I can get a breath of fresh air by skipping past the bang my head against the wall dead-ends and regular difficult hurdles and just get results. Sort of like fast food drive thru. It will be a relief for me. And confidence booster. To see something really happen at a faster pace for a change.

Now none of this is to say I'm abandoning my existing projects. They will all go on as planned without interruption. This will be a parallel journey I will share. I will certainly learn a ton and can apply what I learn to my other projects.

I will have this Hope - Light robot adaptation be named Dinah. I'll use Eve's base mesh for the external appearance. The two females can look similar in build but have different faces.

This robot will use to some extent TheRobotStudio's design philosophy and approach for the Hope-Light project. This means it WILL use metal geared brushed DC servos and it WILL use non-human-like bone structure, but I will still give it human-like realistic silicone skin and it will use the exterior exoskeleton shell of the Eve robot I 3d modeled already. One downside to this Hope-Light parallel implementation is that because it uses metal gearing it will be loud in its operation. So it will never be able to pass for human in public. That's okay though. My other designs are reaching for that aim and my other designs are still the intention for Adam, Eve, and Abel. So that vision remains alive. And will continue. But this noisy robot will still be a great learning experience and capable of doing useful work including helping me build my other robots, chores, manufacturing products, cooking, etc. It will probably do most of the things the Adam, Eve, and Abel robot can do but not be as strong, fast, and articulated. So it will probably not play sports well or do rock climbing or various other serious physical strenuous types of work. But the long list of things it should be able to do is still enough for it to be awesome.

A great thing is that it won't be so experimental and outside the box like my previous solo approaches. This one will be designed to a small degree by a real professional so it will happen way faster and more surely than mine. Although I am finding I am changing his design so much it's not really his design at all anymore but my own. However, I still plan to retain a significant number of strategic decisions, placements, and organization following his lead. My other designs are more of a pipe dream shooting for the moon. Going more similar to this open source one designed by a real pro is more of a "sure thing". Not that I don't believe I can achieve my more ambitious designs, but just that they are admittedly a taller order and more crossing fingers about them is all. I really think building a top tier legit walking and talking full humanoid is going to legitimize my journey more in my own eyes and give me a better resume to bring MORE hope toward my own robot builds. Just seems like doing this is a no brainer.

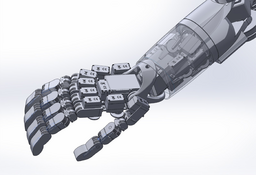

I've attached a early design progress image from TheRobotStudio who is currently designing Hope-Lite in Solidworks.

You'll note he fused the distal knuckle of 4 fingers so they are permanently partly bent. This was a decision to cut down on complexity but in my preference, I'd rather have that functionality. You'll also note that it cannot pronate or supinate the wrist. That takes away a TON of functionality which is not my preference. So my robot will add this function back. That said, as I was studying how to add pronation and supination without a ulna and radius bone, I stumbled across the simple and effective design of posable love dolls' skeletons. I realized they have pronation and supination in their stock skeletons, so I decided I will use that kind of skeleton for this project. They are simple, very strong, welded steel construction with heavy duty hinge systems. To be posable, the hinges are quite stiff, so I will need to loosen all hinges to reduce friction. They are a hollow lightweight tubing style. Actually not that heavy.